Page 62 - Nikko Tools - Update 2019

P. 62

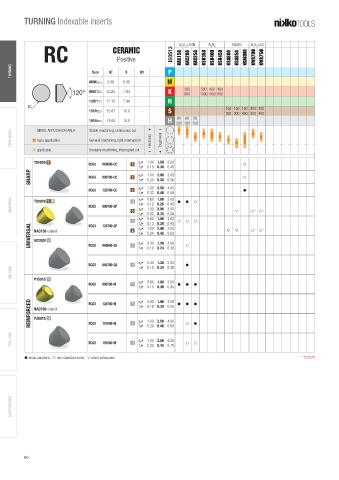

TURNING Indexable inserts

Al O +TiCN Si N SiAlON Al O +SiC

2 3

3 4

RC CERAMIC ISO513 NAC150 NAC200 NAC250 NSN350 NSN400 NSN450 NSA600 NSA650 NSA6000 NWR700 NWR750

2 3

Positive

TURNING Size IC S D1 P

0606 6.35 6.35 - M

300 500 400 400

0907 9.525 7.94 - K

600 1000 1000 800

1207 12.70 7.94 - N

150 150 150 200 200

1510 15.87 10.0 - S

350 300 400 500 400

80 60 50

1910 19.05 10.0 - H

200 180 150

d d d d d

d

d

GRADE APPLICATION AREA

THREADING d main application General machining, light interruption | Hardness + + Toughness | d d d d d d d d d d d

Stable machining, continuous cut

d

Ad

d

d

d

d

d

d

Ad

d

d

d

d

d

d

d

d

d applicable Unstable machining, interrupted cut d d

T01020 S a p£ 1.00 1.50 2.00

RCGX 060600-CC S f

f n£ 0.15 0.30 0.45

SHARP RCGX 090700-CC S a p£ 1.00 2.00 3.00 f

f n£ 0.20 0.38 0.56

a p£ 1.00 2.50 4.00

RCGX 120700-CC S h

f n£ 0.22 0.40 0.58

GROOVING T02020 S H RCGX 090700-GP H f n£ 0.12 0.26 0.40 h h f

a p£ 0.60 1.80 3.00

a p£ 1.00 2.00 3.00

S

f n£ 0.22 0.35 0.58 m f* f*

a p£ 0.60 1.80 3.00

H f n£ 0.13 0.28 0.43 f f f

UNIVERSAL NAC150 coated RCGX 060600-GS S a p£ 1.00 2.00 3.00 f m m f* f*

120700-GP

RCGX

f n£ 0.24 0.42 0.60

S02020 H

a p£ 0.40 1.20 2.00

H

f n£ 0.10 0.24 0.38

a p£ 0.40 1.20 2.00

RCGX 060700-GS H f n£ 0.10 0.24 0.38 h

MILLING

P15015 H

RCGX 090700-HI H a p£ 0.60 1.80 3.00 h h h

f n£ 0.15 0.30 0.45

REINFORCED NAC150 coated RCGX 120700-HI H a p£ 0.60 1.80 3.00 h h h

f n£ 0.18 0.34 0.50

P20015 H

a p£ 1.00 2.50 4.00

f

H

151000-HI

RCGX

h

f n£ 0.20 0.40 0.60

DRILLING RCGX 191000-HI H a p£ 1.00 2.50 4.00 f f

f n£ 0.20 0.45 0.70

h stock standard, f non-standard stock, m stock exhaustion * T01520

ACCESSORIES

60

16/04/2019 15:59:05

03-TURNING Ceramic.indd 60 16/04/2019 15:59:05

03-TURNING Ceramic.indd 60